The Mega-BRIC system is made of stackable servers of 56 portable elementary battery packs called BRIC. Each server has a total capacity of 22.5kWh. This project will involve research and development to improve the Mega-BRIC design and demonstrate that the tech and logic design can meet the requirements of a UPS system with regards to safety, efficiency and availability of the system.

We set out to design an innovative electronic system that allows for the thermal management and diagnostics of batteries on individual cell-level. Our design has a low cost thermal sensor attached to each cell for proactive battery management for the benefit and optimal performance of the entire battery pack. This system is ideal for end-of-life recycling and repurposing, as well as maintenance and servicing.

Leveraging and complementing recent and current projects with Innovate UK, the Faraday Institute, and UK Department for Transport on smart battery system and affordable cargo e-bike for LIC, Alp Technologies has developed a suite of solutions to support urban micro-mobility in LICs.

We are proposing to develop a novel thermal management system by monitoring temperature at individual cell-level in our battery bike system in order to prolong overall battery pack life and maximize individual cell utilization before disposal.

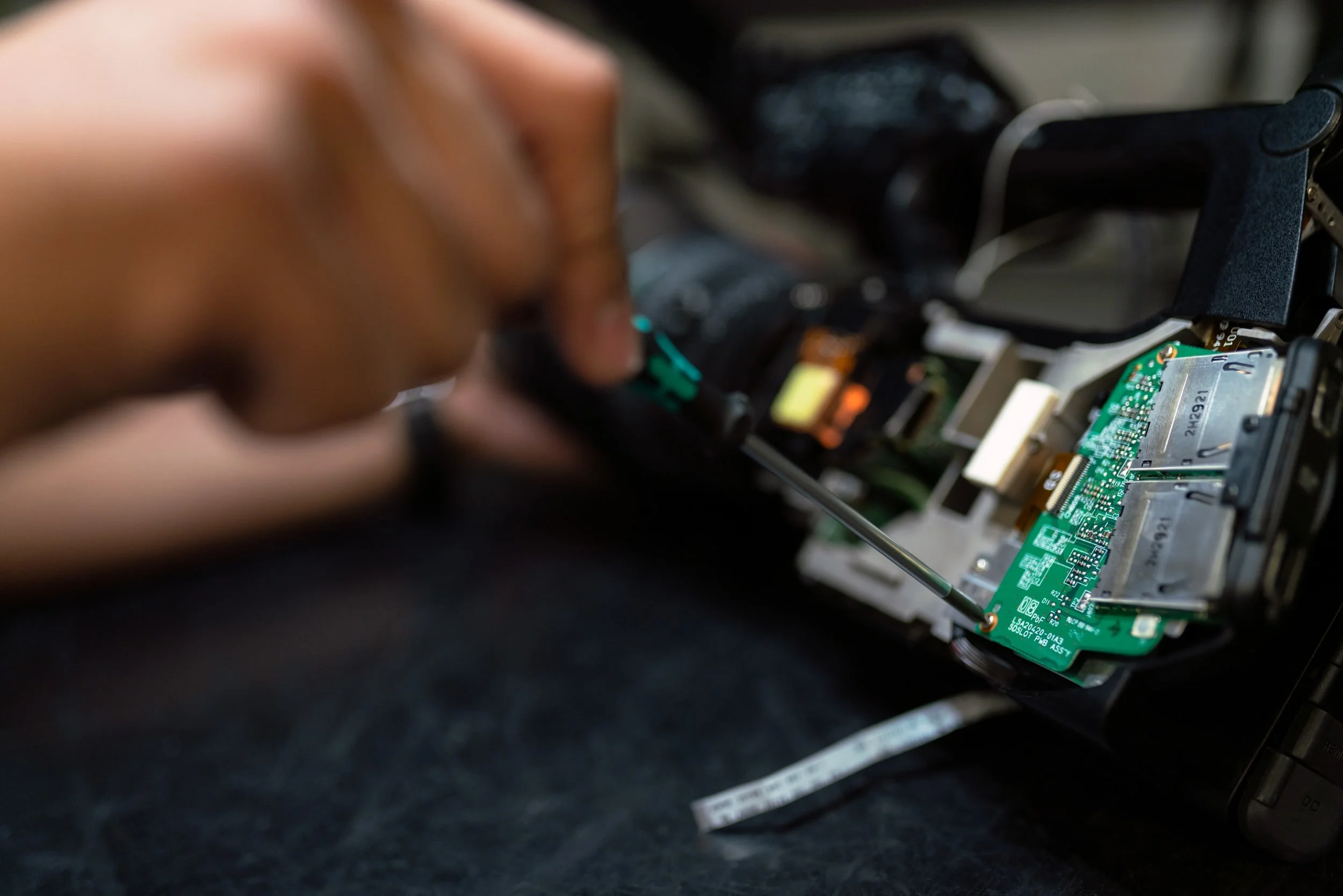

We designed a battery casing for long term use, easy maintenance, and cell replacement to maximize battery pack life and utilization of individual cells. We included innovative compression fittings for battery electrical conductive contacts and ensured that no welding, soldering, or gluing was necessary during assembly.

The objective of our phase 1 project was to promote the use of electric bicycles to expand the cyclist demographic and length of journeys appropriate for a bicycle by reducing the initial and on-going cost of an e-bike battery pack, which is the most expensive component of an e-bike.

We proposed an innovative electronic design which allows for thermal management of batteries and diagnostics performed on individual cell-level. We aim to use low-cost thermal sensors on each cell for proactive battery management, so that we can improve the overall performance of the entire pack.

ALP Technologies began Project Zebra (Zero Emission Vehicle Battery Re-manufacturing for Energy Storage Storage) in April 2017 alongside partners Aceleron and Blue Vine Consultants. The trio will be building a battery pack using recovered energy storage for use with ALP Technologies Biomass Generator.

ALP's hybrid Li-ion storage technology and other micro-CHP innovations overcome the existing challenges of energy conversion of biomass. Our system's ability to produce storable renewable energy in a clean, reliable and efficient manner using biomass alone allows communities to source, transport and consume their own energy at a local and decentralized level.